Processes

Hobbing

Hobbed gears, both spur and helical from 5.0 module (5DP) to 0.4 module (64DP) on state of the art, 5-axis, auto-loaded hobbing machines

Thread Rolling

Precision in-feed and thru-feed rolling of worms and thread forms including trapezoidal and Acme threads with multiple starts with auto loading capabilities.

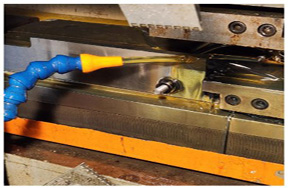

Thread / Worm Milling

Special designed high-speed, dual spindle milling machines to assure tight tolerances and low concentricity

Grinding

Fully automated centerless grinding machines to finish journal and bearing diameters to finished sizes.

Cold Drawing Material

High speed cold drawing equipment with straightening to meet the strictest runout requirements while reducing material costs

CNC Turning

High precision turning of multiple materials from mild steels, stainless, aluminum, brass and threaded rod in diameters up to 25mm.

Crimping and Assembly

Special automated equipment to properly secure components and then check for the correct position

Spline Rolling

Cold forming of various forms or external splines, threads, and grooves.